Lasers are powerful. But raw laser beams are not always useful as they are. Sometimes you need to split them. Shape them. Control them.

That’s where a diffractive optical element comes in. These elements help guide, control, and change light in ways that simple lenses can’t.

Let’s break this down in a way that’s easy to get. No complex words. No over-explaining. Just what matters.

What Is a Diffractive Optical Element?

An optical element, a diffractive optical element (or DOE) , is a miniature optical element. It possesses very minute surface designs known as microstructures that have the ability to alter the actions of a laser beam.

Think of it like this: the surface has a design that bends the light. But instead of using curves like lenses do, it uses tiny lines and shapes. This process is called diffraction.

With the right pattern, the DOE can split a beam, shape it, focus it, or spread it out. It can even create custom light patterns.

These elements are thin. Light. And very precise.

Why Use Diffractive Optical Elements?

Because sometimes a regular lens just can’t do the job. A diffractive optical element gives you more control.

Let’s say you need a laser to cut something, and you want even energy across the surface. You can use a beam shaper design based on diffractive optics.

Or you want to split one laser beam into eight small beams. A diffractive beam splitter can do that easily.

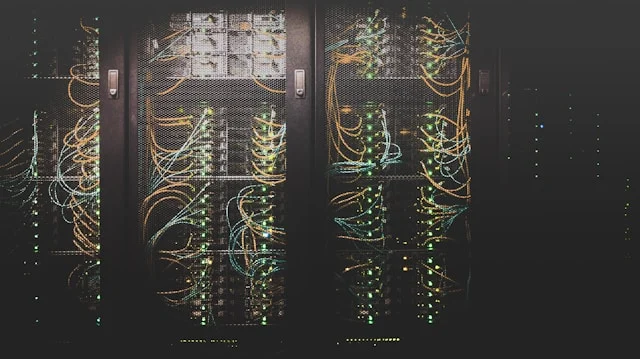

In photonics, semiconductor work, sensors, and optics labs, these elements are everywhere. You may not see them, but they’re doing the hard work behind the scenes.

How Does It Work?

The surface of the diffractive optical element has micro-patterns. When light hits it, it bends and spreads based on the pattern.

That’s diffraction.

It’s different from reflection (like a mirror) or refraction (like a lens). Diffraction gives us more complex and flexible light control.

You can design the DOE to match your laser’s wavelength, so the beam reacts just the way you want.

Some DOEs are flat. Others are curved. Some are pure diffractive. Others are hybrid—mixing lens and diffractive designs.

What Can It Do?

Here are some common things a diffractive optical element can help with:

- Beam shaping – changing the beam profile

- Beam splitting – creating multiple beams from one

- Focusing – with high accuracy

- Custom light patterns – for scanning, imaging, or marking

- Wavelength control – when matched properly

In many systems, you’ll see DOEs working together with other optics. They often sit between a laser and the target, making sure the beam is just right before it hits anything.

Where Are These Used?

You’ll find diffractive elements in a lot of places.

- Semiconductor machines – where high precision is a must

- Medical lasers – like in eye surgeries or skin treatment

- Industrial cutting – where uniform energy is key

- Sensors and detectors – for guiding light onto small targets

- Photonics labs – in testing and research setups

They’re small but powerful. And in today’s world, where lasers are doing more, DOEs are becoming a must.

What Should You Think About Before Using One?

Not every diffractive optical element works with every laser. There are a few things to check first:

- Wavelength – The DOE must match your laser’s wavelength. If not, the pattern won’t work.

- Beam size – You need to know your beam diameter before choosing or designing the DOE.

- Power level – High-power beams can damage poor-quality optics. Make sure the DOE is built for your use.

- System layout – Where in your system does the DOE go? Before the lens? After? In a module?

These things matter. If you’re not sure, don’t guess. It’s better to talk to an expert who works with diffractive optics every day. Even one short discussion can save you money and time.

Final Words

A diffractive optical element isn’t just a tool—it’s a key part of advanced laser systems. It lets you control light in ways that standard optics can’t.

The proper DOE will enable a simple laser to become an effective and precise system as one shapes, splits, and guides a beam. They find use on semiconductor tools, sensors, and photonics among others. And they are increasing in demand.

If you’re unsure which design fits your system, it’s okay. Better to ask now than redo things later. Just speak to someone who works with these elements all day. It’s what they do.

FAQs:

- Why is my laser beam not giving the shape I want?

It could be because you’re not using the right optical element. A beam shaper made with a diffractive optical element can help you get the shape and intensity you need.

- Are DOEs hard to use or install?

Not really. Once designed for your setup, they’re easy to add. But choosing the right one can be tricky. That’s where expert advice really helps.

- Can one DOE work for all lasers?

No. It must match your wavelength and beam type. A DOE made for 1064 nm won’t work well at 532 nm. Always match the element to your laser system.